IT2000M Weighing & Batching module

- W&M approved filling controller, MID compliant, for filling of liquid or solid material

- Beltweigher controller for shipping and receiving of bulk material

- Process weighing terminal for the capturing and/or controlling the throughput of continuous weighers

- Batchweighing terminal for automatic filling in a multi-material batching operation, with connection to host or SCADA system

- Universal, W&M approved, remotely controlled fieldbus terminal with weighing and batching functions, with integrated weight storage (data archive).

Key Features:

- High-precision weight readings and batching on all scales with analog strain gauge load cells,

- Wide range of applications: e.g. filling systems, recipe weighing systems, belt scales, process scales,

- W&M approved use as non-automatic and automatic weighing instrument possible (approved in the EU, USA, Canada, and others),

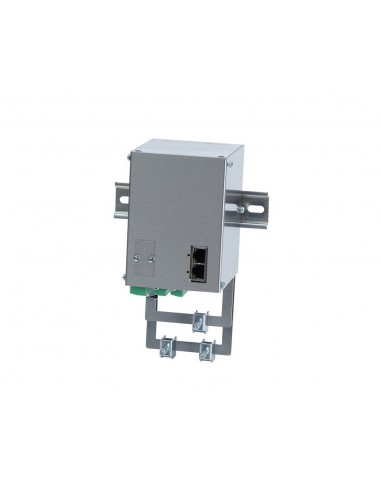

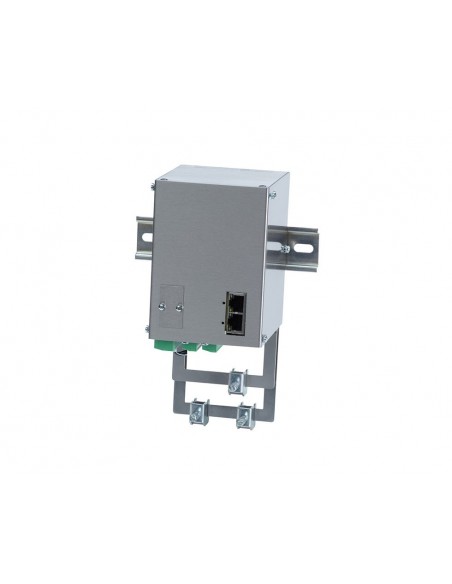

- Compact stainless steel housing (W x H x D: 92 x 120 x 106 mm), protected to IP20, easy installation on hat rail (DIN rail),

- Excellent price/performance ratio,

- High operational security: power-failure proof data storage, password protection, battery-backed realtime clock, remote diagnosis via internet possible.

Fields of application:

- Beltweigher controller for shipping and receiving of bulk material

- Process weighing terminal for the capturing and/or controlling the throughput of continuous weighers

- Batchweighing terminal for automatic filling in a multi-material batching operation, with connection to host or SCADA system

- DEGREE OF PROTECTION

- IP20

IP69K - INSTALLATION

- Back panel mounting on Omega/DIN rail

Desk

Wall - DISPLAY

- LCD

- ANALOG OUTPUT

- 0–20 mA, 4–20 mA, 0–10 V or 2–10 V, 15 bit, 32,000 divisions, for analog output of weight.

- SERIAL PORTS

- RS232

RS485 - POWER SUPPLY

- 12...28 VDC, max. 300mA

12–30 V DC

110–240 V AC, 50/60 Hz - FIELDBUS

- Ethernet/IP

Ethernet TCP/IP - RELAY OUTPUTS

- 2

- LOGIC INPUTS

- 2

No reviews